Truss vs Joists: A Quick Guide to Roof Supports

Two primary components often come into play when constructing a roof: trusses and joists.

Which do we use?

That depends on the size, complexity, and sometimes style of your roof. Both are crucial in supporting and shaping the roof structure but have distinct characteristics and applications. This blog will delve into the differences between roof trusses and joists, helping you understand when to use each.

At Buffalo River Truss, you can trust us for your trussing needs. We emphasize quality raw materials and best welding practices and are specialists in quality steel trusses.

In this blog, we’ll discuss the differences between a truss and a joist – not necessarily which is better, but determining which one you should use depending on the type of project you’re tackling.

Let’s get started!

What Is a Truss?

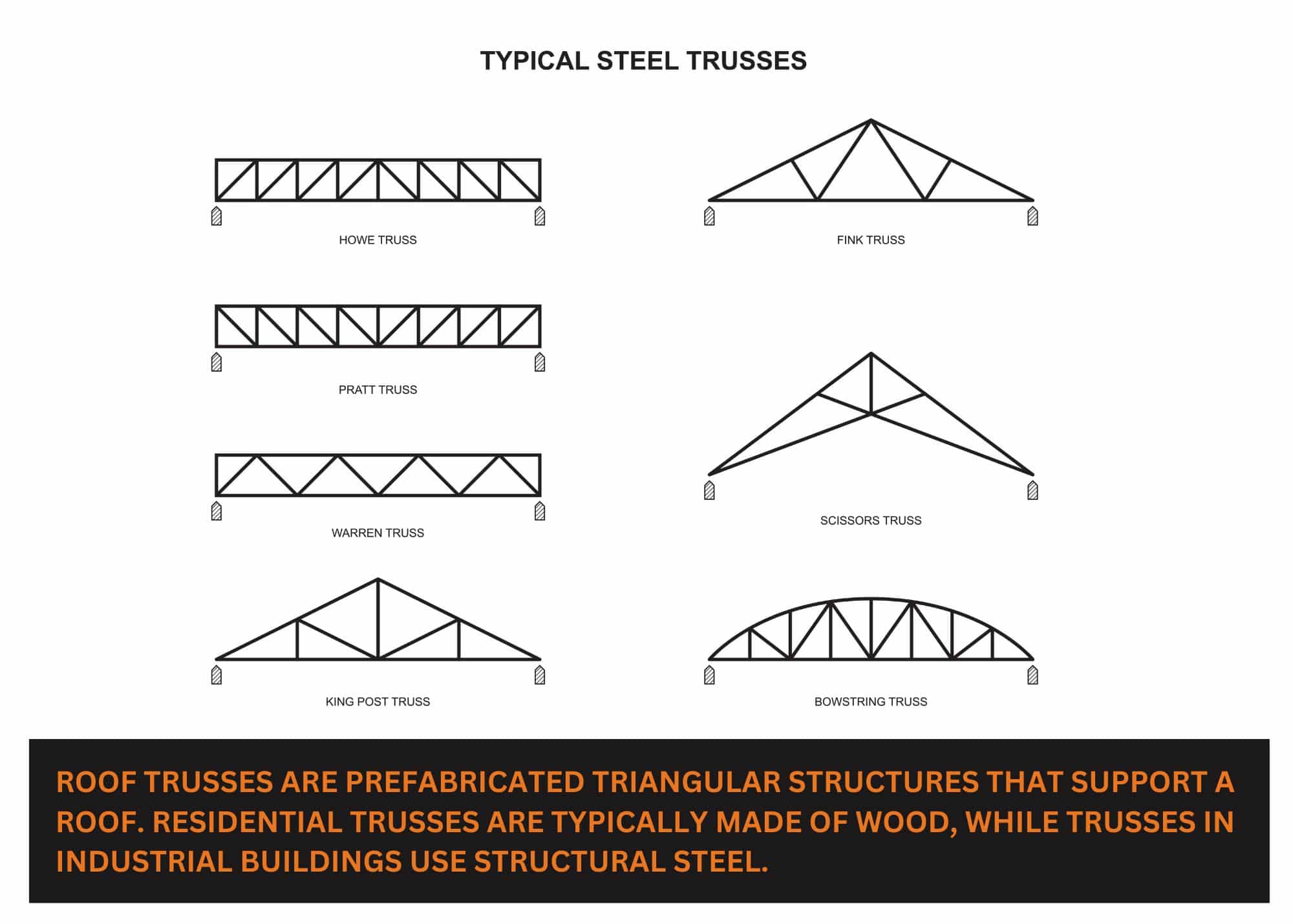

A roof truss is a prefabricated triangular structure that supports a roof. Originally designed as the main structural element of bridges, trusses were engineered to distribute the weight of the roof evenly across the walls of the building.

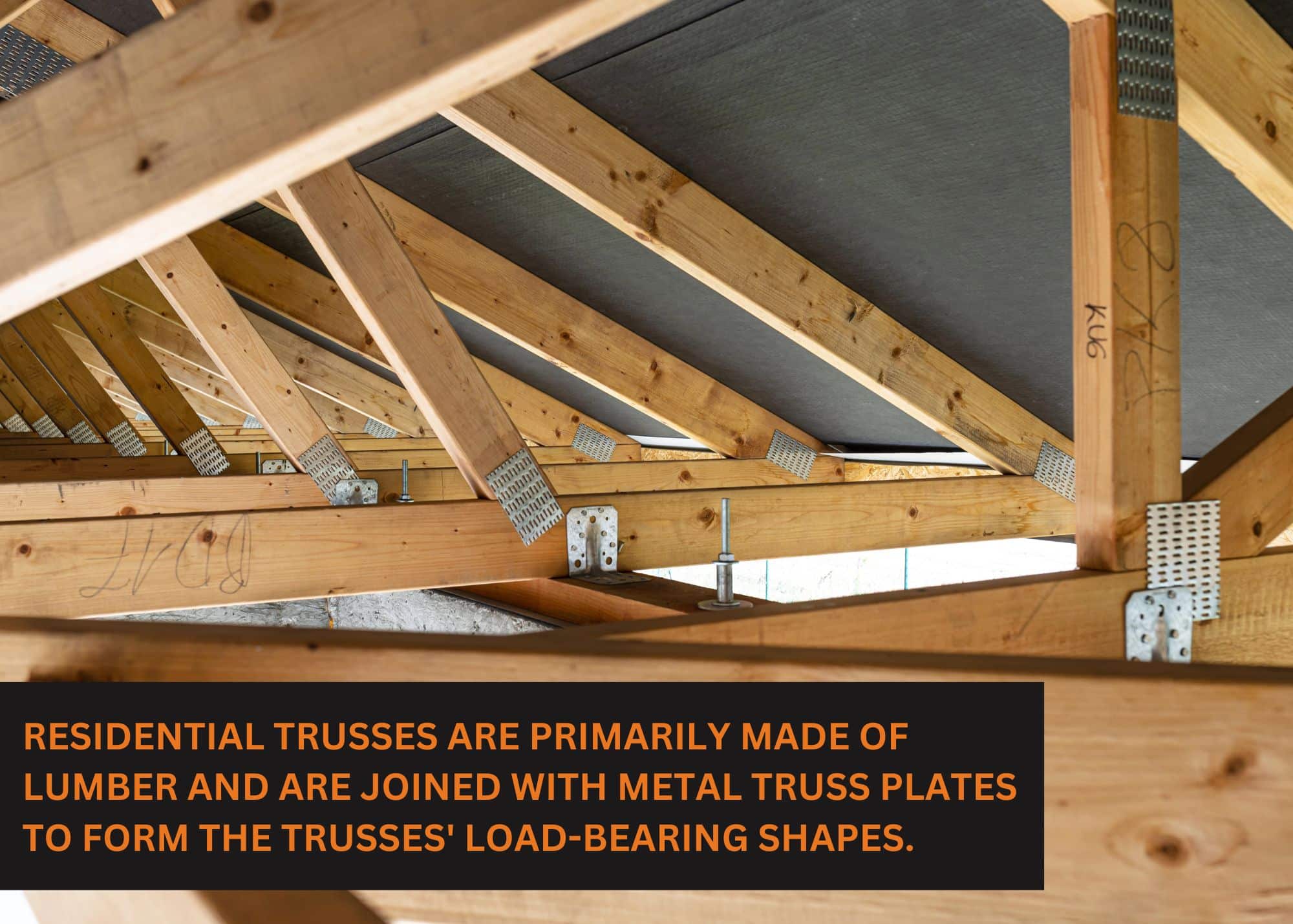

Trusses are typically made of wood or metal and consist of three main parts: the top chord, the bottom chord, and webbing. The top chord forms the roofline, the bottom chord creates the ceiling, and the webbing consists of diagonal and vertical supports that connect the chords. The result is a lightweight structure that looks like a web and is quite a marvel of physics!

While trusses have been used since the early Bronze Age, it wasn’t until Italian architect Andrea Palladio specified truss designs on paper in 1570 that building trusses became an exact science. In 1869, engineer Squire Whipple correctly analyzed the stresses in trusses and published his theories. Understanding precisely how the trusses’ loads were carried led to reduced materials. Combined with the Industrial Revolution, trusses improved in strength and capability as materials shifted from wood and stone to iron and steel.

The modern truss was born in the 1950s with the invention of the metal truss plate and the concept of using it to connect pieces of lumber.

Combined with the introduction of computers and specialized software for designing trusses, the truss industry was also a pioneer in computer-aided design (CAD) in the building industry. These advances, along with many others, created the modern truss industry.

Today, roof trusses are made of wood or metal. Wood trusses are used in house framing, while steel trusses are primarily used in large commercial, industrial, or agricultural buildings. Not all trusses are created equal, though; depending on the application, builders will choose to use different types of truss.

What Is a Joist?

On the other hand, a joist is a horizontal structural element that supports the weight of the floor or roof deck and its loads. Typically made of wood, steel, or engineered wood products, joists are not prefabricated as a single unit but are installed individually on-site. Depending on the load, roof joists vary in size and load specified.

Joists are generally spaced evenly across the roof to support the roof covering. They are used with beams and rafters to create the roof's framework, are suitable for shorter spans, and are often used in traditional construction methods.

The first recorded use of joists was in 14th-century England. They were essentially pieces of dimensional timber laid horizontally (though the word “joist” came from the old French word “geiste,” which means to “lie down”). The modern trusses we see today didn’t exist until the 1970s

However, the wood joists we see in construction, known as I-joists (as they look like the Roman letter “I” when viewed head-on), have only been around for 50 years. The Trus-Joist Corporation invented them in 1969 as an engineered wood product. While I-joists are primarily used for framing floors, their long length and high load capacity have also led to their use as roof rafters.

If you’ve ever been in an old wood house, you’ll notice the floors squeak a lot. This floor is likely held up by traditional dimensional lumber joists. Since dimensional lumber is naturally variable and the wood dries out over time, the movement and friction when you walk on it causes squeaks. Modern I-joists eliminate that problem with consistency built into engineered wood.

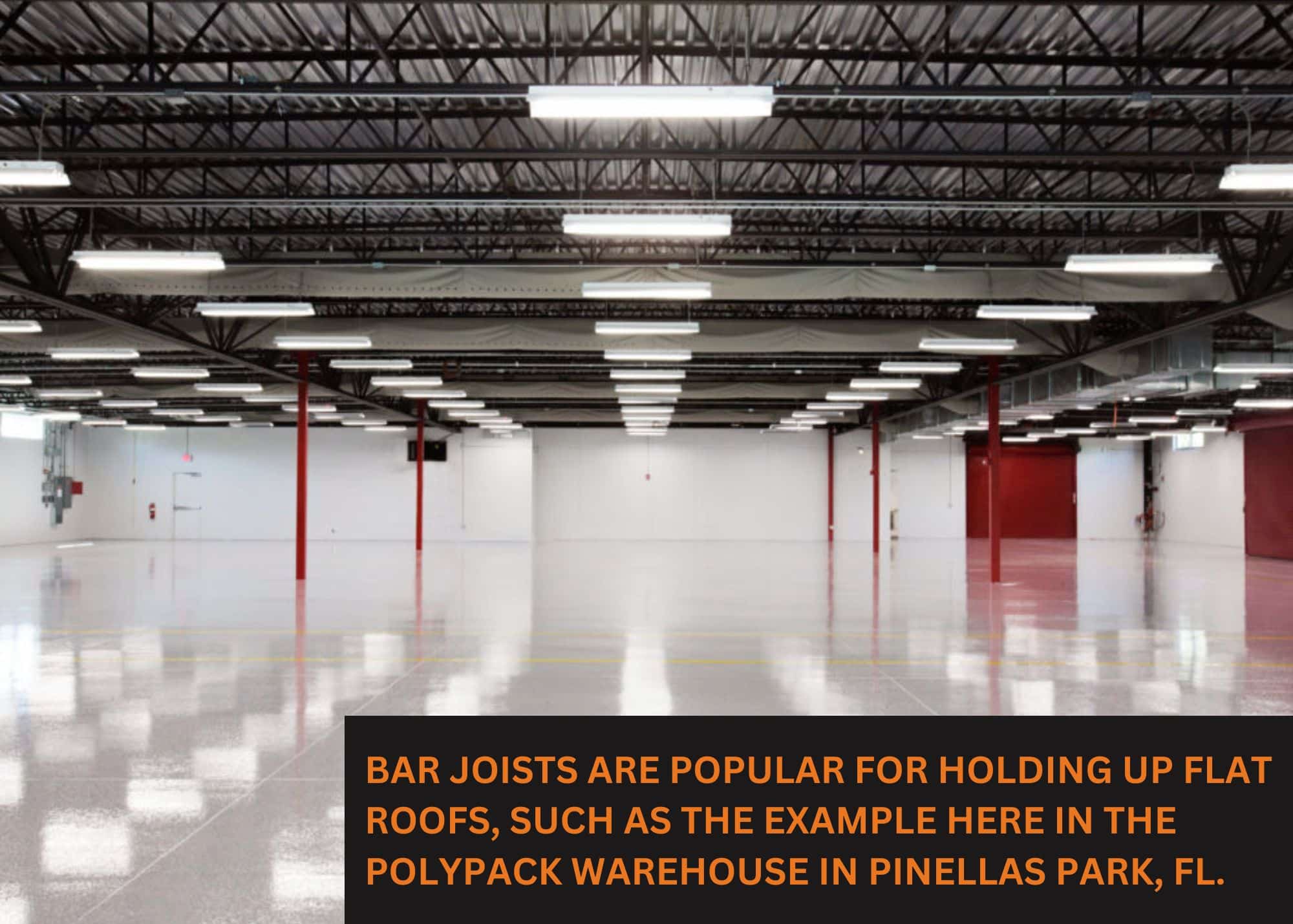

For commercial use, however, roof joists are made of metal for maximum strength and durability. Bar joists are a popular choice for holding up flat roofs.

If you want to know more, we answer all your common bar joist questions here.

When to Use Trusses or Joists

It’s time to put that roof up. Do you use a joist? Or a truss? It’s not as simple as whichever’s cheaper or easier. Let’s talk about how we make these decisions.

Certain situations call for using a truss, where:

- Long Spans Are Required: Trusses are ideal for large buildings or homes with open floor plans because they can span long distances without interior support walls.

- Speed of Construction is a Priority: Trusses are prefabricated and can be installed quickly, reducing labor costs and construction time.

- Consistency and Precision are Needed: Trusses are manufactured in a controlled environment to ensure uniformity and precision, leading to fewer structural issues.

- Complex Roof Designs are Desired: Trusses can be engineered to accommodate complex roof designs, such as vaulted or cathedral ceilings.

Joists are best used where:

- Shorter Spans are Sufficient: Joists are suitable for use in smaller buildings or houses, where long spans are unnecessary.

- Custom Construction is Preferred: Joists allow for more design flexibility and can be adjusted on-site to accommodate specific architectural features.

- Traditional Building Methods are Used: Joists are often used in traditional construction techniques, where builders prefer to assemble the roof structure piece by piece.

- Cost is a Consideration: Joists might be more cost-effective in smaller projects as they can be installed without heavy machinery.

Generally, a truss is more expensive than a joist due to the more complex engineering and manufacturing process involved in creating it. However, the longer spans that trusses can achieve may lead to cost savings in the long run by requiring fewer support beams or posts, making them ideal for structures with large spaces, such as pole barns, riding arenas, agricultural structures, and stadiums that require a significant load-bearing capacity with minimal internal supports.

Builders typically prefer joists for smaller projects with shorter spans due to lower initial costs and less complexity. Because of their lower cost, ease of use, and adaptability, they are a standard fixture in homes and buildings for small businesses built across the United States.

Truss and Joist FAQ’s

Truss FAQs

Now that we’ve discussed the differences between trusses and joists, it’s time to combine the information to understand better how they work.

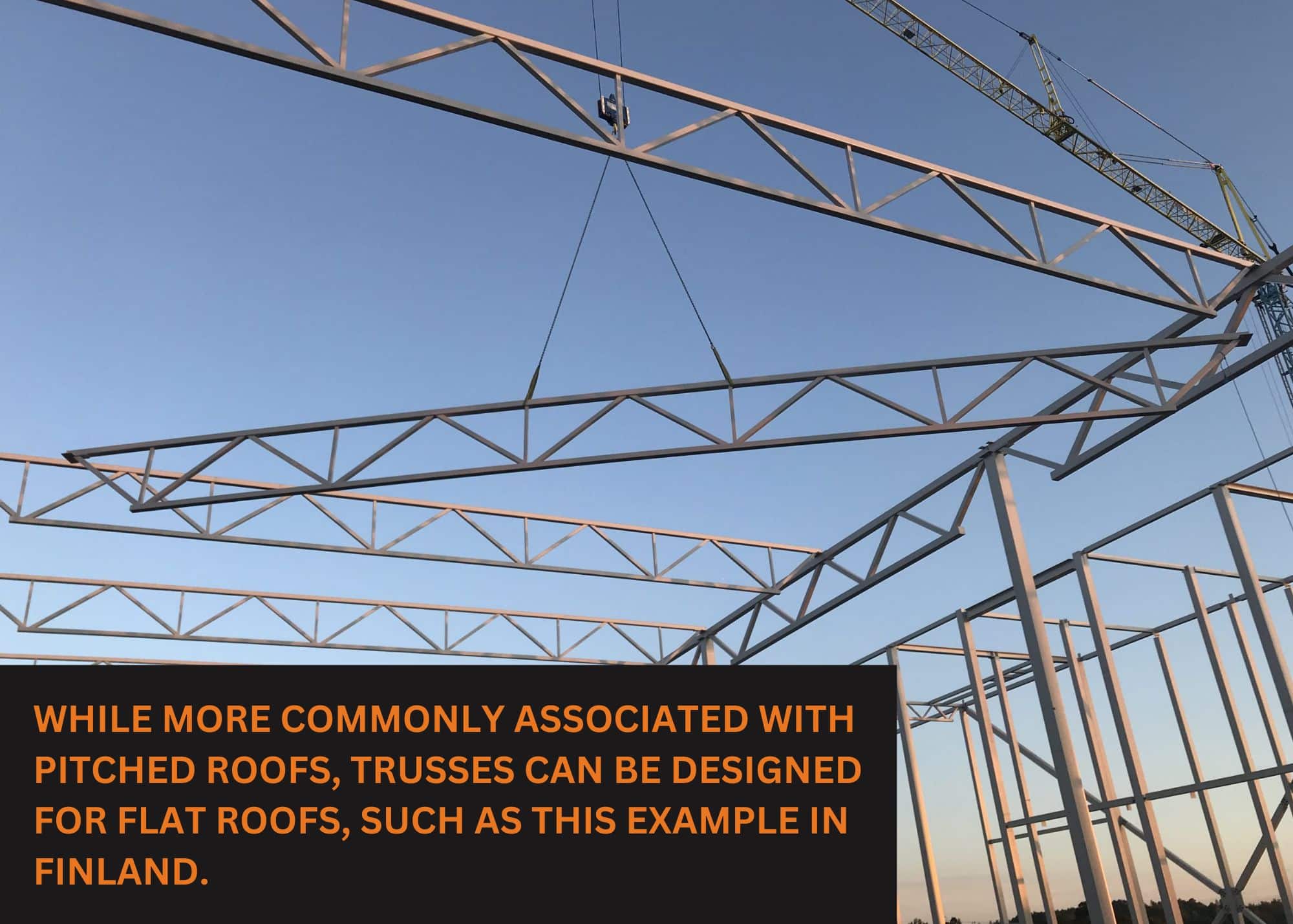

Q: Can trusses be used for flat roofs?

A: Trusses can be designed for flat roofs, although they are more commonly associated with pitched roofs.

The design will differ to accommodate the specific requirements of a flat roof.

Q: Are trusses stronger than joists?

A: Trusses are engineered to distribute loads more efficiently over longer spans, making them stronger for specific applications. However, the strength of a roof system depends on its design and materials.

Q: Can trusses be customized?

A: Trusses can be customized to fit specific architectural designs and load requirements, which may increase their cost and lead time.

Joist FAQ's

Q: What materials are commonly used for joists?

A: Joists are typically made from wood, steel, or engineered wood products like LVL (Laminated Veneer Lumber) or I-joists.

Q: How are joists installed?

A: Joists are installed parallel to each other, spaced evenly across the roof, and secured to beams or walls. They are often installed on-site, allowing for flexibility in the construction process.

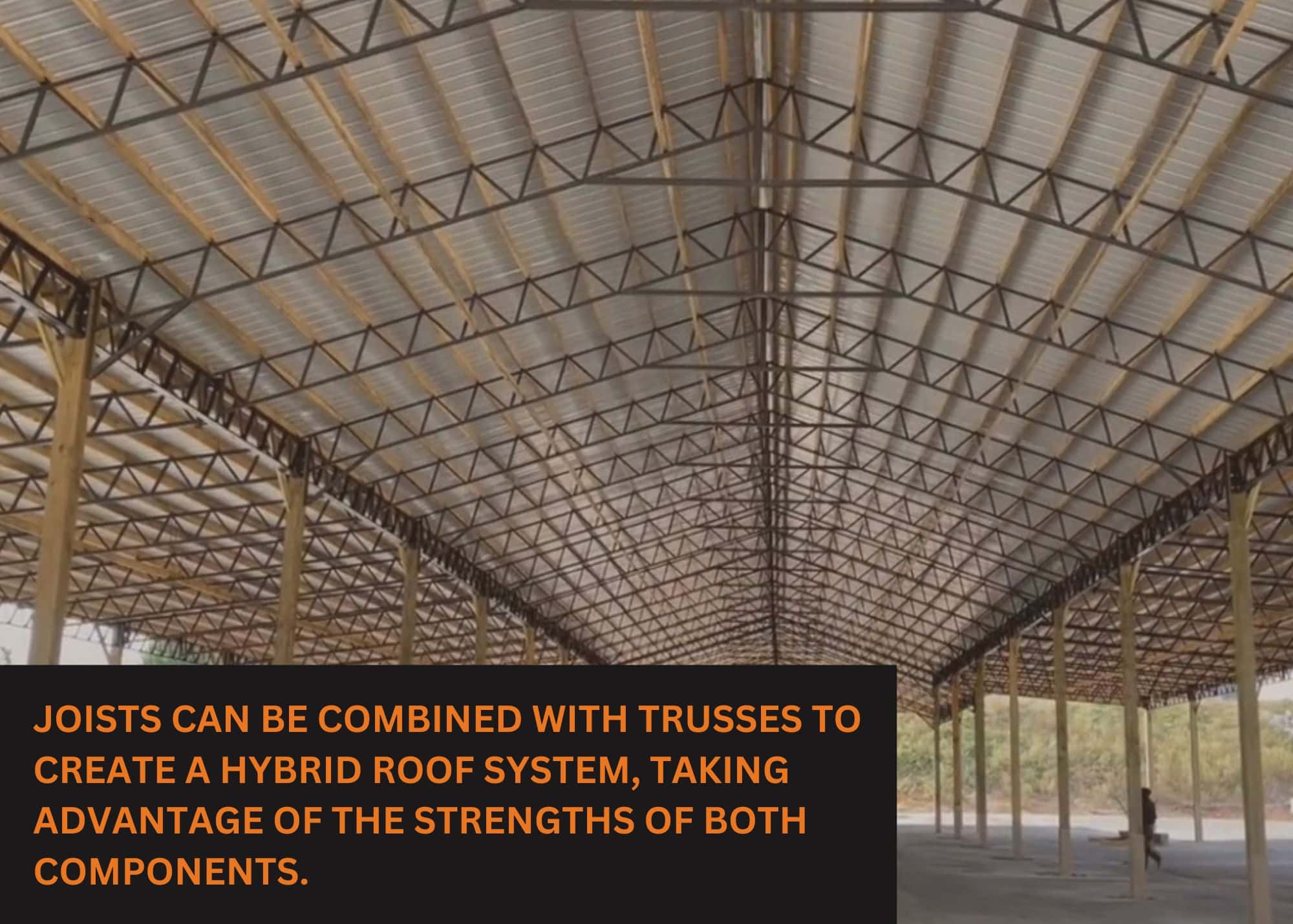

Q: Can joists be used in conjunction with trusses?

A: Yes, joists can be combined with trusses to create a hybrid roof system, taking advantage of the strengths of both components.

Informed Choices and Trusted Partnerships

The choice between roof trusses and roof joists depends on several factors, including the building size, the desired design, the construction timeline, and the budget. Understanding the differences between these two components and their optimal applications can help you make informed decisions for your roofing project. Whether you opt for the precision and efficiency of trusses or the flexibility and tradition of joists, both play a vital role in creating a strong and durable roof structure.

At Buffalo River Truss, we know how important it is to find reliable suppliers in today’s construction industry. That is why we specialize in supplying quality trusses for your building needs. As your partner, we focus on the following so you can focus on completing your project:

- Keeping standard truss sizes in stock for shorter lead times

- Providing engineer-approved drawings for all standard trusses

- Keeping our set of engineer drawings updated and up to code

- Offering trusses up to 100’ in width on a variety of roof pitches

- Prioritizing customer satisfaction through rapid problem resolution

- Keeping high-capacity production and raw materials in stock

Contact us today and learn how we can help truss up your structures!