Understanding Load-Bearing Capacity: How to Choose the Right Steel Truss

The world of structural engineering is vast and complex.

If you are about to start a building project, figuring out all the details might seem overwhelming. What type of foundation do you need? What are the best materials to use? What's the best design?

The list goes on and on.

Today, Buffalo River Truss would like to help you by breaking down the concept of load-bearing capacity in trusses and explaining the basics in understandable terms. That way, you can be more informed about the structural integrity of your building.

Ready to take a dive into the world of truss engineering?

Let’s get started!

Table of Contents

What is a Truss?

Let’s start with the basics: What is a truss, and how does it work?

Well, this is a truss:

And this:

And this:

And this is also a truss:

In brief, a truss is a structural component made up of straight, interlocking members that form a series of triangles. You can spot trusses everywhere: your house, bridges, airports, warehouses, and even the Eiffel Tower all utilize trusses!

But this definition isn’t quite complete. We also need to be able to make two assumptions to consider a structure a truss:

- The structure must have only pinned connections, meaning the members are free to rotate at the joints.

- Loads must be applied only at the joints and never in the middle of a straight member.

All this means that every straight member of a truss is either in tension or compression. Altogether, this keeps the truss stable and enables it to support more weight than any single member could on its own.

Trusses are normally found near the top of a building, supporting either the second story or the roof. Builders use trusses instead of beams because the triangular structures that make up a truss help distribute the load more efficiently.

But now we are getting ahead of ourselves. In the next section, we’ll learn what “load capacity” is and why it’s important in engineering and construction.

What Is Load Bearing Capacity?

We’ve covered trusses – they are a structural component in buildings and are made of lots of triangles. Now, what about truss load-bearing capacity?

Well, the “load” a truss needs to bear may include multiple elements:

- Dead load is the weight of roofing materials, ceiling materials, insulation, and the truss system itself, all of which your trusses need to bear continually.

- Live load is the weight of people or other moving things that may occasionally go up on a roof.

- Environmental load is the weight of snow, the force of wind and rain, or other environmental factors that may put stress on your roof.

A truss’s load capacity is how much weight it can support before the structure fails. In other words, how much of all this stuff can your roof take before it breaks?

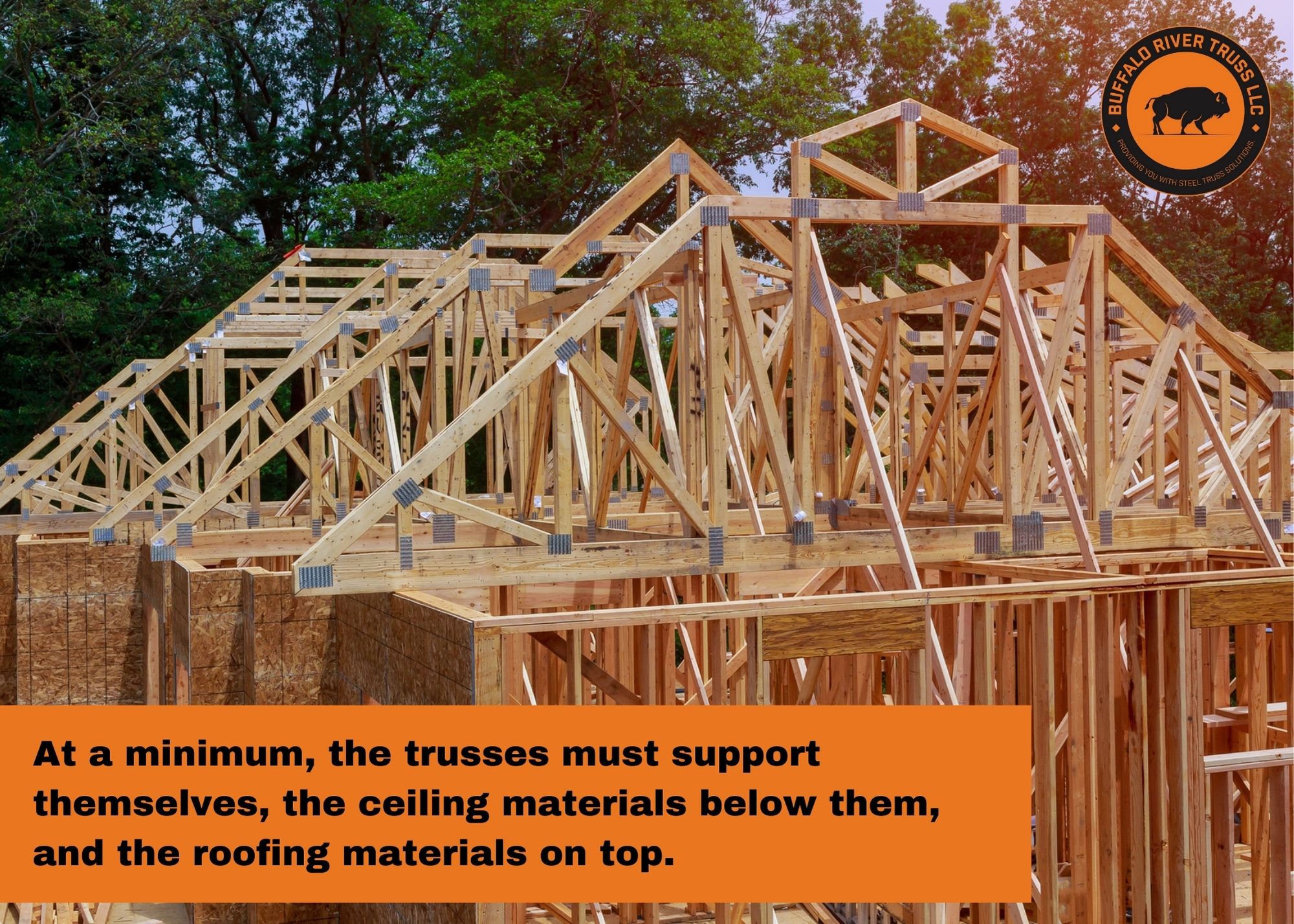

At a minimum, the trusses must support themselves, the ceiling materials below them, and the roofing materials on top. They also need to be able to support a bit more since most structures will encounter some wind, snow, inclement weather, and repairs.

- If your trusses don’t have enough capacity to bear the load of your roof, your structure will fail. That’s why it’s so important to choose the right type of truss for the specific project you are working on. How much weight your roof can hold depends on several factors, and that’s what we will take a look at next, so stay tuned!

5 Factors That Affect Load Bearing Capacity

When working on a building project, you must ensure that your trusses have adequate load-bearing capacity. Otherwise, disaster could strike!

However, load-bearing capacity depends on several factors:

- Material - What material a truss is made of greatly affects its load capacity. For example, a truss design could be manufactured of steel, wood, or engineered wood products. Each would have a different load capacity.

- Design - There are hundreds of different truss designs. There are Howe trusses, Fink trusses, King Post Trusses, and more! Each design has its strengths and weaknesses and may be designed to perform in a specific type of situation. For instance, Warren trusses do well at spanning long distances, whereas North Light Trusses are generally used for shorter spans.

- Spacing - How close you space trusses also affects load capacity. The closer you set them, the more evenly the load is distributed, which results in higher capacity.

- Load distribution - If the load is distributed evenly across the entire truss, the load-bearing capacity increases, as opposed to the load being concentrated at one spot on the truss.

- Span - Span refers to the distance a truss can cover unsupported. In other words, it’s the distance between two walls, pillars, or other supports the truss can span and remain stable. Generally, a truss’s load-bearing capacity decreases as the span increases. Some truss designs are more effective at spanning long distances than others.

You need to consider all these factors and probably a few more that are specific to your situation when deciding what type of truss is suitable for your building project. After all, your trusses must have adequate load-bearing capacity or your structure may fail!

If you aren’t familiar with construction and engineering, you should get an architect or builder to help you with your design plans so you can design a safe building.

There are also things you may do that can drastically reduce the load-bearing capacity of your trusses.

For example, modifying an engineered truss in any way is a terrible idea. Never cut, drill, notch, or otherwise alter a truss. Even drilling a hole for an electrical line can compromise the truss and reduce its load capacity.

Say you want access to your attic. Never cut through the bottom web of a truss to create your opening! Trusses are designed to remain stable only as long as they remain whole. Cutting through that bottom web will throw the truss out of equilibrium and seriously compromise it!

If your trusses are ever damaged, call an expert right away.

Choosing Trusses With The Right Load Bearing Capacity For Your Project

As we said, it’s absolutely crucial that your trusses have adequate load-bearing capacity. Otherwise, your roof will fail, and you will have serious consequences.

So how can you choose the right trusses?

That’s a complicated question, and in reality, it all depends on your specific situation. But in short, you’ll need to take a look at all the factors that affect load capacity (see previous section) and assess what you need.

If you don’t know much about construction, we recommend you find an architect or builder who does and have them assess your situation. A standard 2x4 Fink roof truss may be the best option for some designs. For others, steel bar joists could be a better option.

There are so many types of trusses out there, and likely you’ll have several different options that could be suitable. If you are unsure, it’s best to get expert advice–your trusses are not something you want to mess around with!

Conclusion

Now you know what load-bearing capacity is for trusses and how it affects the structural integrity of your building.

You also know why choosing the right type of truss for your next building project is important.

At Buffalo River Truss, we understand this too! That is why we manufacture quality steel trusses for pole barns, ag structures, riding arenas, or other buildings. The type of steel truss we make offers several benefits, including increased headroom/storage space, faster install times, improved aesthetics, and better structural integration.

We make getting your steel trusses easy:

- Contact Buffalo River Truss

- Scheduling and engineering

- Delivery

After that, install your trusses and enjoy your new building!

We would love to hear from you–call us today to learn more!