Metal Trusses: Advantages, Disadvantages, And FAQs

If you are building a pole barn, riding arena, agricultural facility, or other large structure, you will need a light, strong material for the framing.

Wood is a good choice for most structures, but today Buffalo River Truss is here to help educate you on another option for framing your roof: metal trusses.

We'll take a look at the advantages and disadvantages of using metal trusses and make sure to cover all the commonly asked questions. At the end, you'll be able to make an informed decision on whether metal trusses are a good option for you.

Let’s get started!

Table of Contents

What Are Metal Trusses?

What is a truss?

If you are not a construction worker you may not know exactly what a truss is. Here is a brief explanation:

Trusses are the components of your roof that make up the main frame and support the weight of the other roofing materials. They play the same role as rafters but are a little more complicated since they are designed to hold more weight over a longer span. Instead of just a single board like a rafter, trusses are made with a top chord, a bottom chord, and bracing in between.

Bracing holds the top and bottom chords together with triangular shapes. These triangular shapes help distribute the weight of the roof over the entire truss and down the sides of the building. Having the weight distributed evenly allows the truss to span a longer length and support more weight without collapsing.

Because of their load-bearing capacity, trusses are generally used for large structures like airports, riding arenas, or storage facilities, where you need to span a long distance.

What are trusses made of?

If you are building a structure and need trusses, you have two main options: Wood or metal trusses. Wood works well for many structures, but it has several disadvantages. For one thing, wood is susceptible to pests, moisture, and decay. On top of that, wood is not capable of supporting heavy weight over long spans, and wooden trusses often take longer to install than metal trusses.

Because of these issues, many people prefer metal trusses to wooden ones.

What types of trusses are there?

Trusses come in various shapes and forms depending on the type of project they're being used for. If you'd like to know more about the various types of trusses, read our blog post on the seven common types of trusses.

6 Advantages Of Using Metal Trusses

Although there are some cases where wooden trusses are the best option, metal trusses have significant advantages for most projects. Here are a few reasons you might want to choose metal for your next building.

-

Enduring strength and quality

Trusses made from metals such as steel will last far longer than any type of wood. Because they are made from non-organic materials, metal trusses are not susceptible to pests such as mold, termites, other insects, or natural decay. If properly treated, they are not susceptible to moisture damage, even if left out in full exposure to the elements.

But there’s more. Metal isn’t just durable, it’s also incredibly strong.

For example, steel can bear heavy loads of snow without buckling. That makes it an excellent choice for areas that get a lot of snowfall or other extreme weather such as hurricanes, ice storms, and heavy winds.

-

Fire resistance

As well as being resistant to decay, rot, and moisture damage, steel trusses are basically impervious to fire too. That is not to say that your building will never burn if it has steel trusses, but at the very least a building with metal components takes longer to collapse, giving you more time to evacuate.

Their fire resistance makes metal trusses especially desirable in areas with frequent storms, wildfires, or seismic activity, all of which increase the chances of a structure fire.

-

Increased headroom in large buildings

If you are stacking hay or other products in a barn you want to be able to stack it right up to the ceiling so you don’t waste any space. And if you are driving tall machinery around in a building, you want plenty of headspace to avoid unintended accidents.

The design of metal trusses allows for more headspace in your building so you can make use of all the space you can. Alternatively, wooden trusses tend to allow for less headspace which wastes space and makes it hard to maneuver large machinery inside.

-

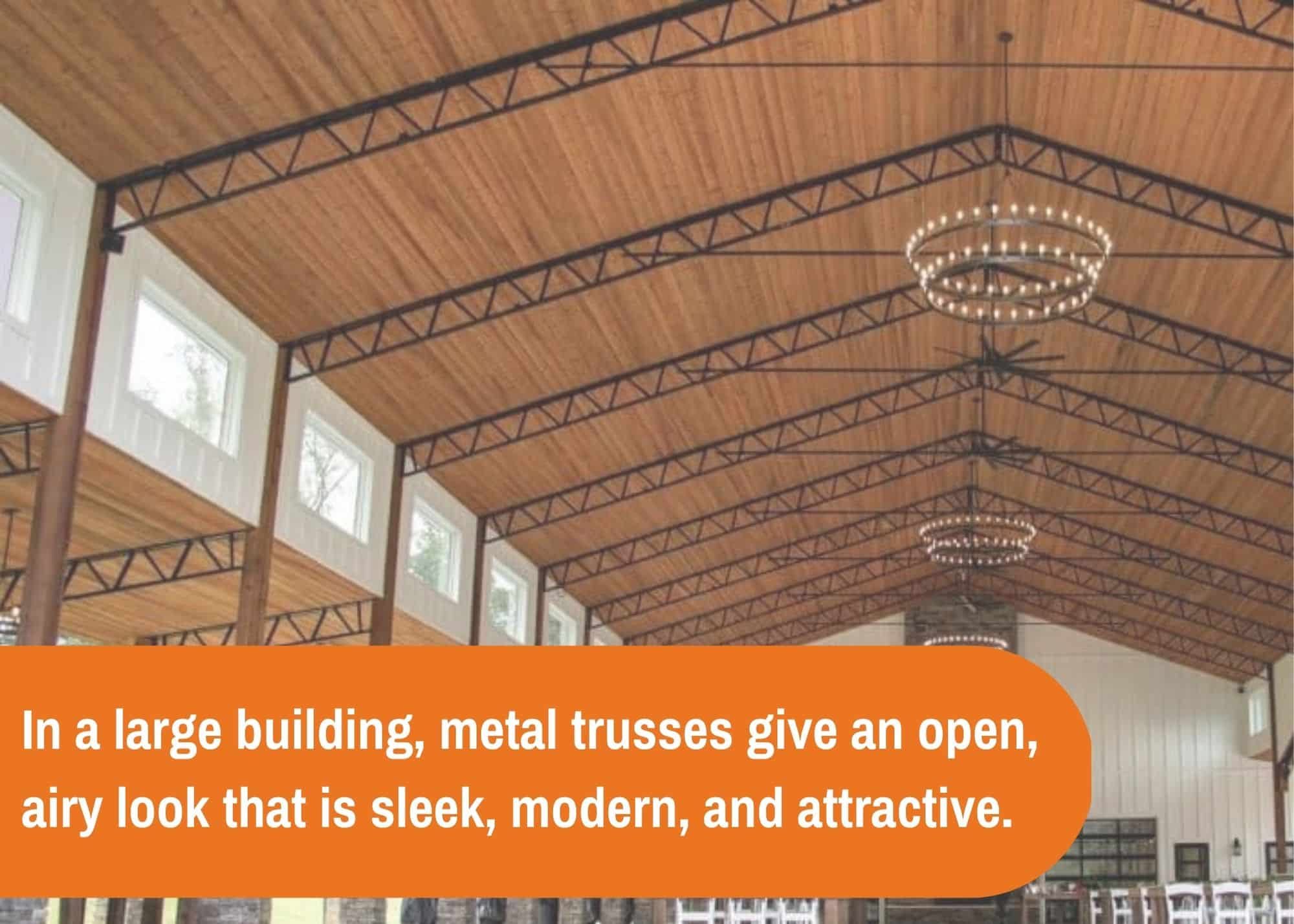

Better aesthetics

Wood has a beautiful, natural look. But in a large building, metal trusses give an open, airy look that is sleek, modern, and attractive. That is partly because metal trusses are more streamlined than most wooden trusses, and partly because you can space your metal trusses further apart since they are stronger than wood. This lends itself to a more spacious aesthetic.

In other words:

If you want your building to look attractive on the inside, metal trusses are the way to go for both aesthetics and durability.

It’s a win-win!

-

Eco friendly

Steel is a 100% recyclable material. Many steel trusses are manufactured from recycled steel, and if you ever need to dispose of the trusses, they will be completely recyclable.

-

Faster install time

Since metal rafters are manufactured in a factory and shipped to the construction site, they generally take less time to install. Also, since they are often lighter than wooden trusses, they don’t always require a crane for installation.

But the main reason they take less time than wooden trusses is that you need fewer of them since you can space them further apart. The fewer trusses you need to install, the less time it takes.

4 Disadvantages of Metal Trusses

There are a lot of good things about metal trusses, but they do have a few downsides as well. Here are a few reasons why you might not want to use metal trusses.

-

Rust

Well-made metal trusses should last for years. However, while they aren’t susceptible to rot, pests, or moisture damage, they are susceptible to rust in corrosive environments. Protective coatings can make this less of an issue, but sometimes the trusses can still rust around a drill hole, scratch, or other small flaws.

The rusting problem makes metal rafters a poor choice for highly acidic or marine environments.

-

Less sound insulation

If you use metal in your structure your building may be louder than a wood-framed building. That is because wood is a naturally good sound insulator, whereas metal is not.

-

Less energy efficient

Metal is a much better conductor than wood. That means that more heat will escape from a building with metal trusses than with wood, making it harder to heat the building.

-

Require skilled labor to install

In general metal trusses require more specialized labor for installation. It’s a bit harder to cut, drill, and work with the metal trusses on-site than it is to work with wood. Also, when you work with metal trusses you run more risk of electric shock, since metal is such a good conductor.

Metal Truss FAQs

Since you probably still have questions about metal trusses, let's review a few commonly asked questions.

-

What kind of buildings are metal trusses used for?

Metal trusses are most often used for large buildings such as riding arenas, storage or agricultural facilities, gyms, pole barns, or shops.

-

How are trusses different from rafters?

A rafter is a single piece of wood, whereas a truss is constructed from a top chord, bottom chord, and webbing connecting the two. Because of this trusses can bear more weight than rafters.

-

Are metal trusses cheaper than wood?

That can depend on your project. Metal trusses cost more per truss. However, since wooden trusses are much weaker. You have to space them closer together and have to use more of them. So the price difference may not end up being as large as you think.

-

How far apart do you put metal trusses?

Steel trusses can be spaced up to 12 feet apart. Compare that to the standard 2-4 feet for wooden trusses!

That means that:

- You need much fewer metal trusses for a building than you would wooden trusses, and

- Metal truss installation is much faster than wooden truss installation.

Conclusion

Now you know a bit more about metal trusses and why you may want to use them for your next building project. We hope this article has been helpful.

If you are interested in learning more about metal trusses and whether they are a good choice for you, contact us here at Buffalo River Truss!

We have worked with a variety of trusses for years, and we offer quality steel trusses in the South-central US region.

Why work with Buffalo River Truss?

- We keep standard truss sizes in stock for shorter lead times.

- We get engineer-approved drawings for all our standard trusses.

- We keep our set of engineer drawings updated and up to code.

- We offer trusses up to 100’ in width, for a variety of pitches.

- We offer rapid problem resolution for our customers.

- We keep all our materials in stock to make for rapid production.

Give us a call today! We look forward to hearing from you.

quote on 96ft wide gable trusses, 3/12 pitch. no overhang. to be connected to a 6×6 wood column/post. If 8ft on center need 19. If 10ft on center need 15.